LUBRICANT

SMART SENSOR

Static Lubricant

Condition Monitoring

ABOUT

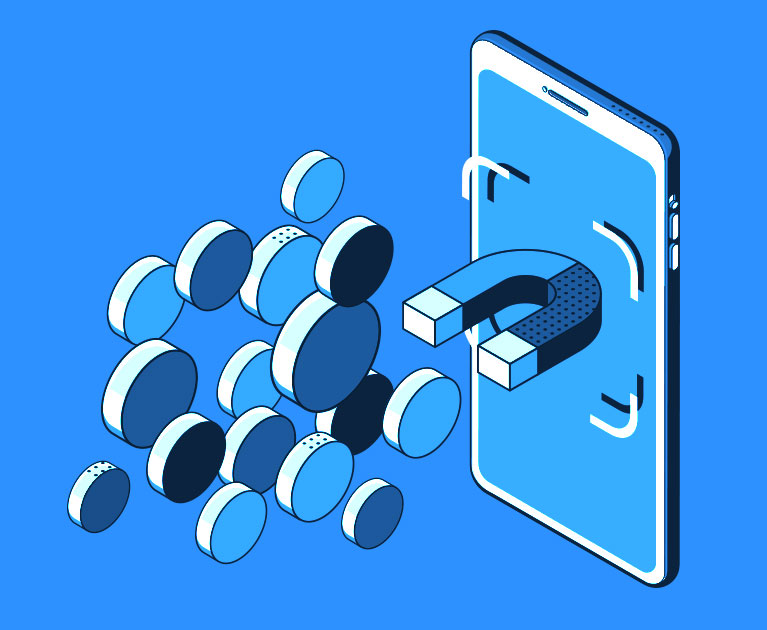

The SLA 106 is a lubricant condition particle counting monitoring sensor.

One of the best tools for condition-based machinery preventive maintenance. A powerful neodymium magnet attracts the worn particles.

Our sensor reads the concentration of the large and small particles separately, a great help to know the type of wear in progress.

The sensor is secured by replacing the plug oil drain and screw in place.

Our Mesh network allows the installation of hundreds of sensors that report to a single Gateway.

FEATURES

SPECIFICATIONS

RELATED PRODUCTS

Connectivity Products

Connect your sensors to the cloud

Smart Vibration Sensor

Keep your machinery up and running!

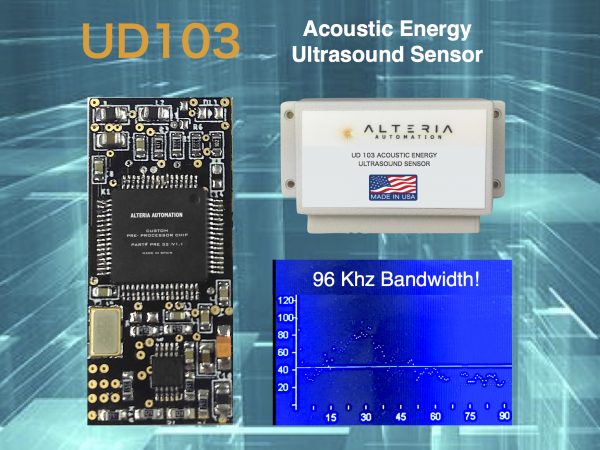

Acoustic Energy Sensor

Detect failure before it happens!

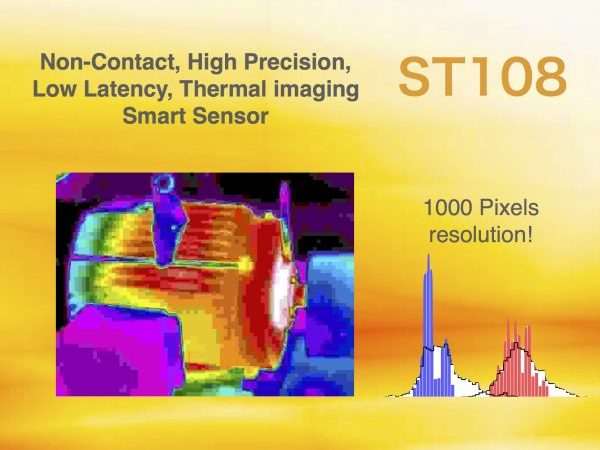

Smart Thermal Sensor

Pre-procesed thermal imaging!

Lubrication Sensor

Get real-time lubricant condition!

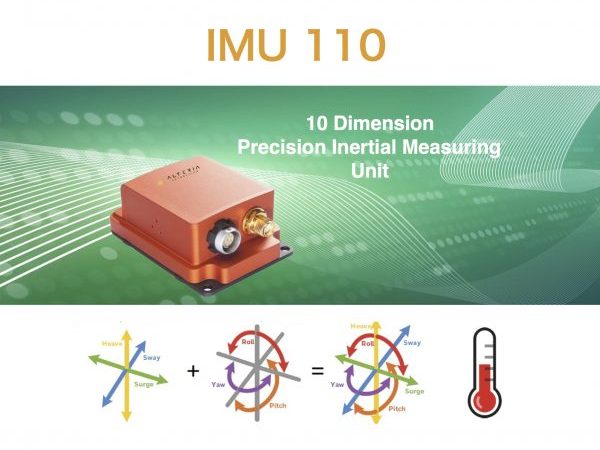

Inertial Measuring Unit

Measure any kind of movement with ease!

HAVE QUESTIONS?

Give us a call or drop by anytime, we endeavour to answer all enquiries within 24 hours on business days.

Error: Contact form not found.