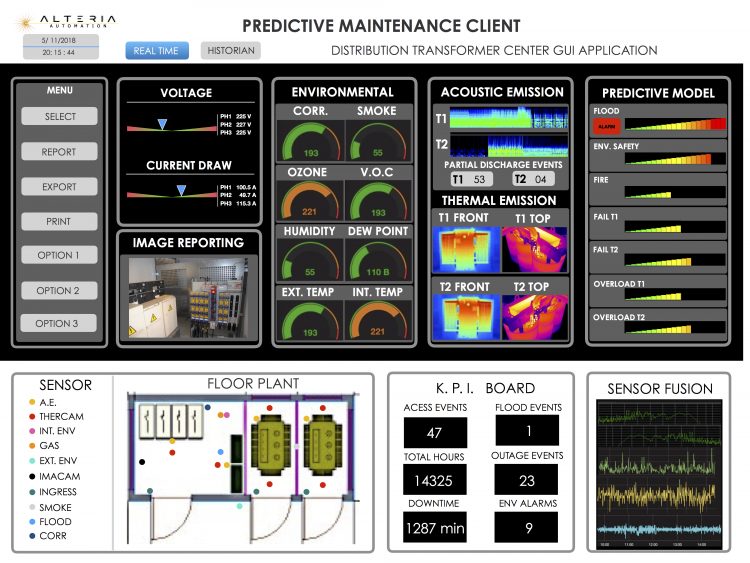

ALTERIA AUTOMATION is the leading provider of Industrial Sensors for Predictive Maintenace

Smart Sensors with Pre-Processing.

Wired and Wireless Connectivity.

Artificial Intelligence Software Packages.

Discover more

PREDICTIVE MAINTENANCE PRODUCTS

Our primary focus is to provide cost-effective Smart Sensors, Connectivity products and Data analysis server solutions to Industry, Transportation and Aerospace

SMART SENSORS

Sensors in Stock, If you are looking for a special sensor, we got it!

Products-at-a-Glance

Need a custom sensor? You got it!

Connectivity Products

Connect your sensors to the cloud

Smart Vibration Sensor

Keep your machinery up and running!

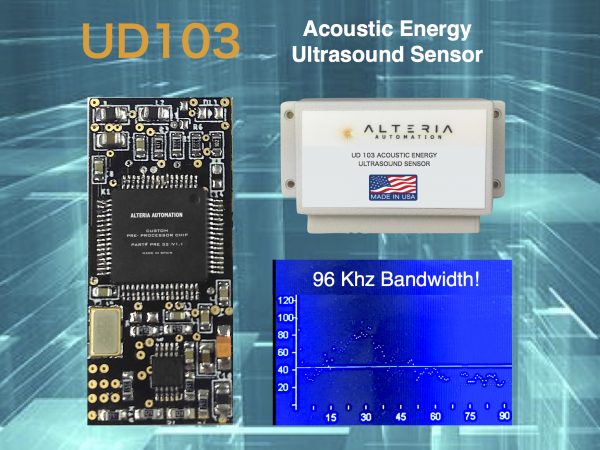

Acoustic Energy Sensor

Detect failure before it happens!

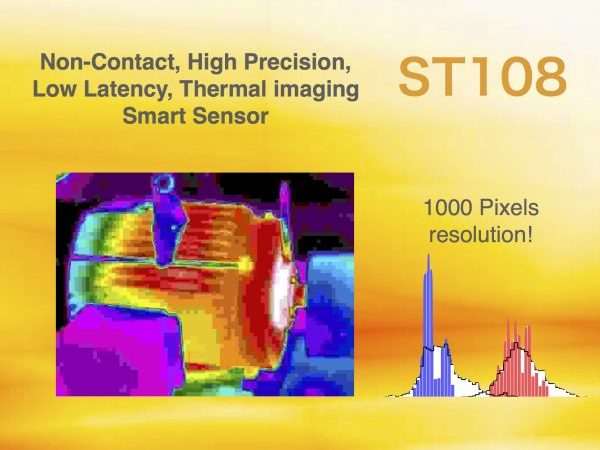

Smart Thermal Sensor

Pre-procesed thermal imaging!

Lubrication Sensor

Get real-time lubricant condition!

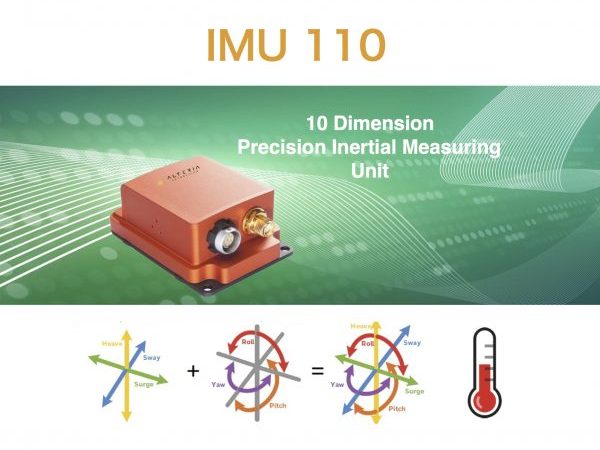

Inertial Measuring Unit

Measure any kind of movement with ease!

Trusted by the best Industries

ACTION PLAN

This is how to start implementing Industrial I.o.T. in your Company

-

1

Proof Of Concept and target definition

Industrial I.o.T. is a revolutionary technology that is changing how we work. We recommend starting with a P.o.C. to demonstrate how our technology can help.

-

2

Project development process and integration

After the P.o.C. is complete, the evaluation of the data gathered will help to redefine specific targets such as process optimization or predictive maintenance models.

-

3

Roll-out an full implementation

The third step is the full implementation of I.o.T. technology. Gathering and analyzing data for a few months will deliver results and the creation of models to improve the process.

VIDEO PRESENTATION: OUR TECHNOLOGY

CASE STUDIES

Steel Galvanizing Plant

Scratch detection

Textile Laser Processing

Vibration detection

Wind generators maintenance

Gear box service

Automotive Plant

Robot predictive maintenance